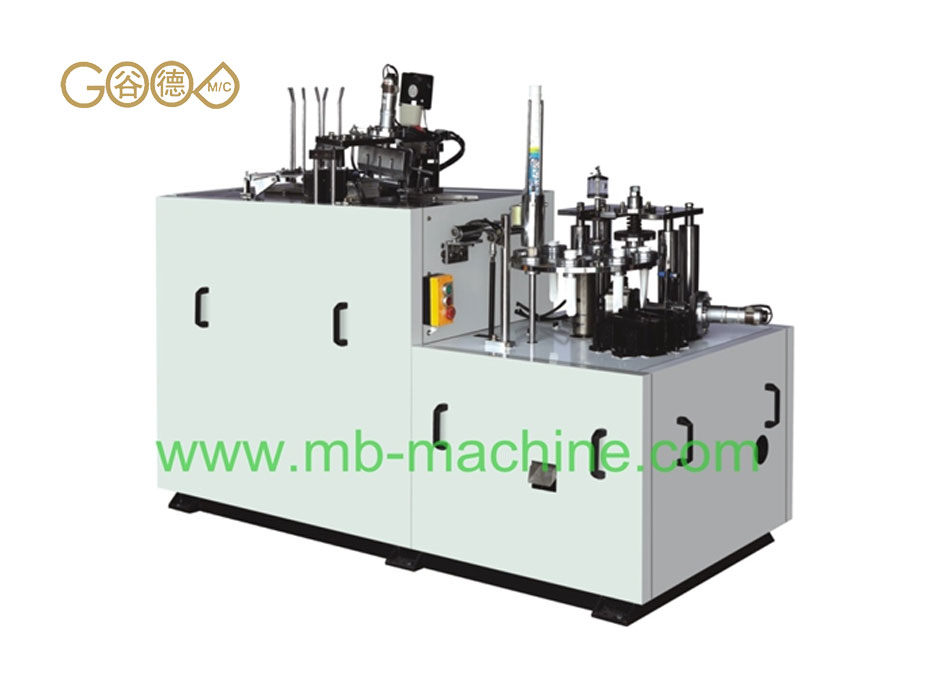

MB-T09

Callipo Tube Forming Machine

It can automatic feed paper fan ,weld by ultrasonic or heater system(binding the cup wall),oiling, cup top rolling bottom sealing (by ceramnic hot air system, high temperature and fast sealing, durable and clean air. Banko brand), cut the bottom to be curve, discharge the waste edges automatically, and finished tube delivery, in a continually process, test through photoelectric cell, and alarming upon encountering troubles and counting. It is a good equipment to produce ice cream cups (tubes).

Main Technical Data:

Raw material: Single side and double side PE(polyethylene) film coated paper

Suitable paper weight: 170--250 gsm

Max cup top diameter: 50 mm

Max cup length: 202mm

Angle: 2-4°

Speed of making paper cups: 40 -50 pcs per minute

Total power: 5 KW

Power source: 220V AC

Whole machine weight: 1200 kg

Appearance size(L x W x H): 2260 x 1030 x 1900 mm

Specification:

Automatic control adopts optically controlled non-contact switch,

Micro-controlled inverter,

Step-less speed adjustment,

Easy changing molds to produce different sizes paper cups,

Easy operating (one operator is enough),

Easy maintenance with minimum cost,

Cheap operating cost and low investment,